Usiland Optronics, a professional laser cleaning machine manufacturer & supplier!

Usiland Optronics Laser Cleaning Machine Supplier Laser Cleaning Machine Suppliercompany

Company Advantages

· Usiland Optronics laser cleaning machine supplier is scientifically designed based on the experience of users.

· This product is cost-effective and the quality is exceptional.

· Providing the best quality laser cleaning machine supplier is the purposes of SUZHOU USiLAND OPTRONICS CO.,LTD.'s service.

Related Parameters

| Project name | Parameter data |

| Self-healing beat [sec] | 120 |

| Silent cotton beat [sec] | 60 |

| Laser cleaning [W] | 500/fiber laser/double-station |

| Tyre inspection | Automatic weighing detection |

| Tyre size [inch] | 16 - 22 |

| Spongy form | Full size / subsection |

| Sponge Binding agent | Self sealer / Binding agent |

| Sponge feeding method | Parent roll / Automatic cutting |

*Glue applicator: four-dimensional gluing device

*The above standard is 235/45R18 inch

Main Performance Parameters Of Production Line

Main Performance Parameters Of Production Line:

Silent tire production index 1: 60s (adhesive coated, dual laser cleaning, @245/45R18).

Quiet tire production index 2:120s (coated with self-sealing adhesive, single laser cleaning @245/45R18).

Self-healing tire performance index: 180s (self-sealing adhesive full coating, single laser cleaning, @245/45R18).

Automatic silent tire production line

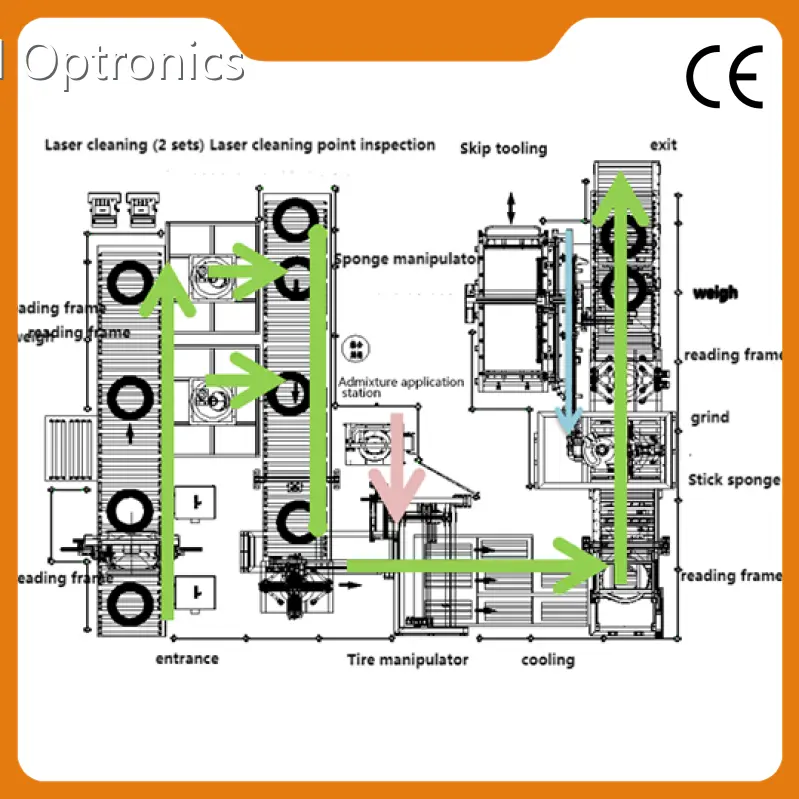

Production line wrokflow

Pump glue system

Pump glue system (self-sealing glue)

1. Adopt standard drum packing form.

2. The system pump glue pressure can reach 30MPa before the glue gun is exported, the pump glue speed is 0.75L/min, the system temperature control deviation is +2C, and the maximum temperature of the system is 210℃.

3. The pump rubber piston can realize automatic exhaust function, real-time automatic feedback of the material level, and automatic feedback system can prompt the refueling cylinder when the rubber material is near the end.

4. The pressure of the primary pump is built, and the secondary quantitative pump accurately guarantees the glue supply (deviation 2%).

5. The system piston disc, primary pump, secondary pump, rubber valve and conveying pipeline all have heating function, temperature feedback function and pressure measurement function. When the system replaces the rubber material, only need to heat the new rubber material to extrude the residual rubber material in the original system. Hot melt adhesive can be heated repeatedly within the appropriate temperature range.

System workflow

Silent tire system

Pump glue system (adhesive)

1. Standard drum packaging, (55 gallons).

2. The system pump glue pressure can reach 10MPa before the glue gun is exported. Primary pump 90cc metering pump 35cc.

3. The pump rubber piston can realize automatic exhaust function, real-time automatic feedback of the material level, and automatic feedback system information to prompt the refueling cylinder when the rubber material is near the end.

4. The pressure of the primary pump is built, and the secondary metering pump accurately guarantees the glue supply (deviation 2%).

5. The system is distributed to four groups of glue nozzle, at the same time coated with 3-8mm, thickness of 2-5mm adhesive.

Pump Glue And Glue Coating System

1. The first stage pump is pressed into the rubber barrel with the pressure plate. The first stage pump is a gear pump, and the adhesive is pumped into the high pressure pipe through the gear meshing. The adhesive enters the metering pump through the high pressure pipe, and the output flow rate of the metering pump is a constant value (in the same raw material, the same inlet and outlet pressure difference) and the accurate measurement of the transported adhesive is carried out.

2. The adhesive enters the rubber valve through the bipolar high-pressure pipe. The rubber valve opens the valve port and enters the rubber nozzle. The adhesive is coated on the inner surface of the tire in a certain shape through the shape of the rubber nozzle.

3. In order to ensure the stability of the glue output, it is equipped with four metering pumps, glue valves, glue nozzle, and output four adhesive channels at the same time. One spin of the tire completes the adhesive coating.

Gluing System

Four Dimensional Module Introduction

DOF 1: 1#, 2# switch between stations.

DOF 2: Control the glue height and distance.

DOF 3: synchronous movement with the tire to achieve gluing.

DOF 4: The rubber applicator rotates to fit the shape of the tire section.

Advantages Compared With Robots

1. The four-dimensional module and the tire rotating motor are in the same PLC system, which can achieve high-precision synchronous motion and higher winding accuracy.

2. The rotation of the glue gun only requires a small amplitude movement of the 4th degree of freedom axis and the rotation of the robot glue gun requires a multi-axis coordination to complete, and the motion range is large and its advantage is reflected in the four-dimensional module structure can adapt to a wider range of tire specifications than the robot.

3. imple and clear structure, convenient follow-up maintenance and low maintenance cost.

Coverage Effect Photoes

The following is the coating effect

Laser Cleaning System

Laser cleaning form:

1. Linear cleaning.

2.Two-dimensional cleaning.

Compared with the two methods, the two-dimensional cleaning energy density distribution is more uniform, the efficiency is relatively high and the corresponding cost is relatively high. Laser cleaning device equipped with independent cleaning room, dust removal equipment and visible fire alarm, etc.

Sponge Fit Effect

Sponge fit host

- Sponge fit host.

- Pressure detection device.

- Sponge feeding system.

Display Cases

Demonstration of sponge bonding effect

Company Features

· SUZHOU USiLAND OPTRONICS CO.,LTD. is a well-known manufacturer of laser cleaning machine supplier.

· SUZHOU USiLAND OPTRONICS CO.,LTD. is equipped with a full set of imported equipment. SUZHOU USiLAND OPTRONICS CO.,LTD. has been rigorously selecting high-tech and new environmental protection laser cleaning machine supplier. SUZHOU USiLAND OPTRONICS CO.,LTD. has advanced manufacturing technology and processes.

· We want satisfied customers to trust our products for a long time. We know that the image and name of a brand can only gain real value if it can see good works behind it. Inquire!

Product Details

With the pursuit of excellence, Usiland Optronics is committed to showing you unique craftsmanship in details.

Application of the Product

The laser cleaning machine supplier produced by our company can be applied to different fields and scenarios. So the different requirements of different people can be satisfied.

In addition to providing high-quality products, we also provide effective solutions based on the actual conditions and the needs of different customers.

Product Comparison

Compared with peer products, Usiland Optronics's laser cleaning machine supplier has the outstanding advantages, mainly reflected in the following aspects.