Usiland Optronics, a professional laser cleaning machine manufacturer & supplier!

For Railway Laser Cleaning Machine Manufacturer by Usiland Optronics

Company Advantages

· laser cleaning machine manufacturer Design: Simple, bright, economical and practical.

· We are striving forward to try to achieve the great performance of laser cleaning machine manufacturer to make it more practical for customers.

· SUZHOU USiLAND OPTRONICS CO.,LTD. better understands the needs of users and provide quality services.

Related Parameters

| Project name | Parameter data |

| Self-healing beat [sec] | 120 |

| Silent cotton beat [sec] | 60 |

| Laser cleaning [W] | 500/fiber laser/double-station |

| Tyre inspection | Automatic weighing detection |

| Tyre size [inch] | 16 - 22 |

| Spongy form | Full size / subsection |

| Sponge Binding agent | Self sealer / Binding agent |

| Sponge feeding method | Parent roll / Automatic cutting |

*Glue applicator: four-dimensional gluing device

*The above standard is 235/45R18 inch

Main Performance Parameters Of Production Line

Main Performance Parameters Of Production Line:

Silent tire production index 1: 60s (adhesive coated, dual laser cleaning, @245/45R18).

Quiet tire production index 2:120s (coated with self-sealing adhesive, single laser cleaning @245/45R18).

Self-healing tire performance index: 180s (self-sealing adhesive full coating, single laser cleaning, @245/45R18).

Automatic silent tire production line

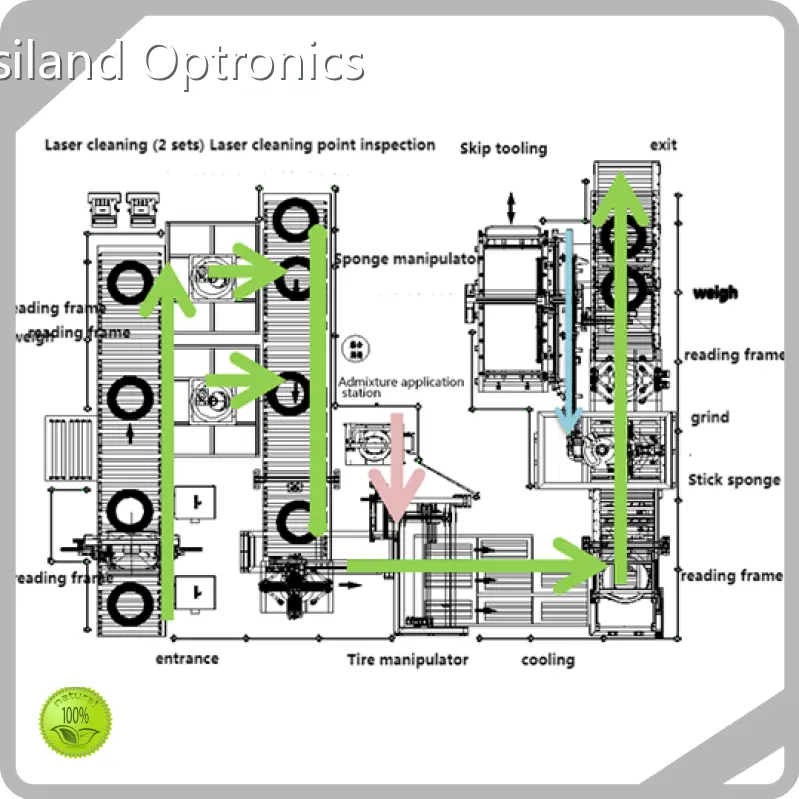

Production line wrokflow

Pump glue system

Pump glue system (self-sealing glue)

1. Adopt standard drum packing form.

2. The system pump glue pressure can reach 30MPa before the glue gun is exported, the pump glue speed is 0.75L/min, the system temperature control deviation is +2C, and the maximum temperature of the system is 210℃.

3. The pump rubber piston can realize automatic exhaust function, real-time automatic feedback of the material level, and automatic feedback system can prompt the refueling cylinder when the rubber material is near the end.

4. The pressure of the primary pump is built, and the secondary quantitative pump accurately guarantees the glue supply (deviation 2%).

5. The system piston disc, primary pump, secondary pump, rubber valve and conveying pipeline all have heating function, temperature feedback function and pressure measurement function. When the system replaces the rubber material, only need to heat the new rubber material to extrude the residual rubber material in the original system. Hot melt adhesive can be heated repeatedly within the appropriate temperature range.

System workflow

Silent tire system

Pump glue system (adhesive)

1. Standard drum packaging, (55 gallons).

2. The system pump glue pressure can reach 10MPa before the glue gun is exported. Primary pump 90cc metering pump 35cc.

3. The pump rubber piston can realize automatic exhaust function, real-time automatic feedback of the material level, and automatic feedback system information to prompt the refueling cylinder when the rubber material is near the end.

4. The pressure of the primary pump is built, and the secondary metering pump accurately guarantees the glue supply (deviation 2%).

5. The system is distributed to four groups of glue nozzle, at the same time coated with 3-8mm, thickness of 2-5mm adhesive.

Pump Glue And Glue Coating System

1. The first stage pump is pressed into the rubber barrel with the pressure plate. The first stage pump is a gear pump, and the adhesive is pumped into the high pressure pipe through the gear meshing. The adhesive enters the metering pump through the high pressure pipe, and the output flow rate of the metering pump is a constant value (in the same raw material, the same inlet and outlet pressure difference) and the accurate measurement of the transported adhesive is carried out.

2. The adhesive enters the rubber valve through the bipolar high-pressure pipe. The rubber valve opens the valve port and enters the rubber nozzle. The adhesive is coated on the inner surface of the tire in a certain shape through the shape of the rubber nozzle.

3. In order to ensure the stability of the glue output, it is equipped with four metering pumps, glue valves, glue nozzle, and output four adhesive channels at the same time. One spin of the tire completes the adhesive coating.

Gluing System

Four Dimensional Module Introduction

DOF 1: 1#, 2# switch between stations.

DOF 2: Control the glue height and distance.

DOF 3: synchronous movement with the tire to achieve gluing.

DOF 4: The rubber applicator rotates to fit the shape of the tire section.

Advantages Compared With Robots

1. The four-dimensional module and the tire rotating motor are in the same PLC system, which can achieve high-precision synchronous motion and higher winding accuracy.

2. The rotation of the glue gun only requires a small amplitude movement of the 4th degree of freedom axis and the rotation of the robot glue gun requires a multi-axis coordination to complete, and the motion range is large and its advantage is reflected in the four-dimensional module structure can adapt to a wider range of tire specifications than the robot.

3. imple and clear structure, convenient follow-up maintenance and low maintenance cost.

Coverage Effect Photoes

The following is the coating effect

Laser Cleaning System

Laser cleaning form:

1. Linear cleaning.

2.Two-dimensional cleaning.

Compared with the two methods, the two-dimensional cleaning energy density distribution is more uniform, the efficiency is relatively high and the corresponding cost is relatively high. Laser cleaning device equipped with independent cleaning room, dust removal equipment and visible fire alarm, etc.

Sponge Fit Effect

Sponge fit host

- Sponge fit host.

- Pressure detection device.

- Sponge feeding system.

Display Cases

Demonstration of sponge bonding effect

Company Features

· After years of involvement, SUZHOU USiLAND OPTRONICS CO.,LTD. has become a highly-qualified manufacturer of laser cleaning machine manufacturer. We have strong capacities in designing and manufacturing innovative products.

· Our factory has sophisticated machines and equipment. These facilities help us reduce our reliance on manual labor and waste of raw materials.

· SUZHOU USiLAND OPTRONICS CO.,LTD. strives to be a stable laser cleaning machine manufacturer global market supplier.

Enterprise Advantages

Usiland Optronics focuses on the cultivation of scientific and technological talents. At present, a team of experienced experts and elite personnel has been established to provide a strong guarantee for product development.

With a deep understanding of customers' needs and market, our company can provide customers with convenient pre-sales consultation and perfect after-sales service.

With the pursuit of excellence, Usiland Optronics highly values services and mutual benefit in the business cooperation. The enterprise spirit is to develop with innovation and keep pace with the times. We practice the development strategy and actively assume social responsibility. We are committed to providing quality products and professional services.

Usiland Optronics has been engaged in the industry for years. We have rich industry-related experience.

At present, our company's domestic business is spreading throughout South China, East China and North China. And we are ready to open up overseas market based on the mature domestic market.